KnowledgeECONOMICS

CONTACT US

Hunan Perfect Industry Co.,Ltd

Contact: Manager Hu, Manager Yi

Hotline:008618507312158

Cell phone:008613974960765

Address:Xiangyin County Industrial Park, Yueyang City, Hunan Province, China

Current location: HOME »Knowledge »vertical turbine pump

Suspended semi submersible vertical turbine pump inlet vibration reduction and vortex prevention device

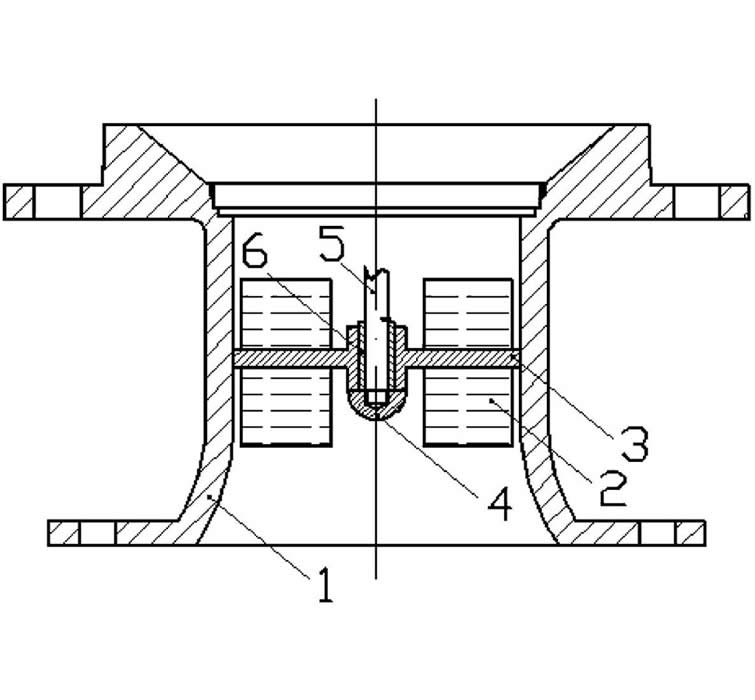

The inlet vibration reduction and vortex prevention device of the suspended semi submersible vertical turbine pump is installed at the inlet of the suspended semi submersible vertical turbine pump, consisting of a horn inlet, guide vanes, guide bearings, impeller nuts, shaft and shaft sleeve connections. The guide bearings are connected to the horn inlet, the guide vanes are connected to the guide bearings, and the shaft and shaft sleeve are installed in the guide bearings. The lower part of the horn inlet is connected to the filter flange, and the upper part of the horn inlet is connected to the volute flange; This technical method basically eliminates the pre rotation of the suspended semi submersible vertical turbine pump inlet when the pump is running, and the guide bearing can effectively reduce the vibration of the pump shaft end, optimize the pump inflow conditions, and extend the service life of key pump components.

Technical requirements: 1. A suspended semi submersible vertical turbine pump inlet vibration reduction and vortex prevention device, characterized by: comprising sequentially connected horn inlet, guide vane, guide bearing, impeller nut, shaft and shaft sleeve; The guide bearing is connected to the horn inlet, the guide vane is connected to the guide bearing, the shaft and shaft sleeve are installed in the guide bearing, the lower part of the horn inlet is connected to the filter flange, and the upper part of the horn inlet is connected to the volute flange.